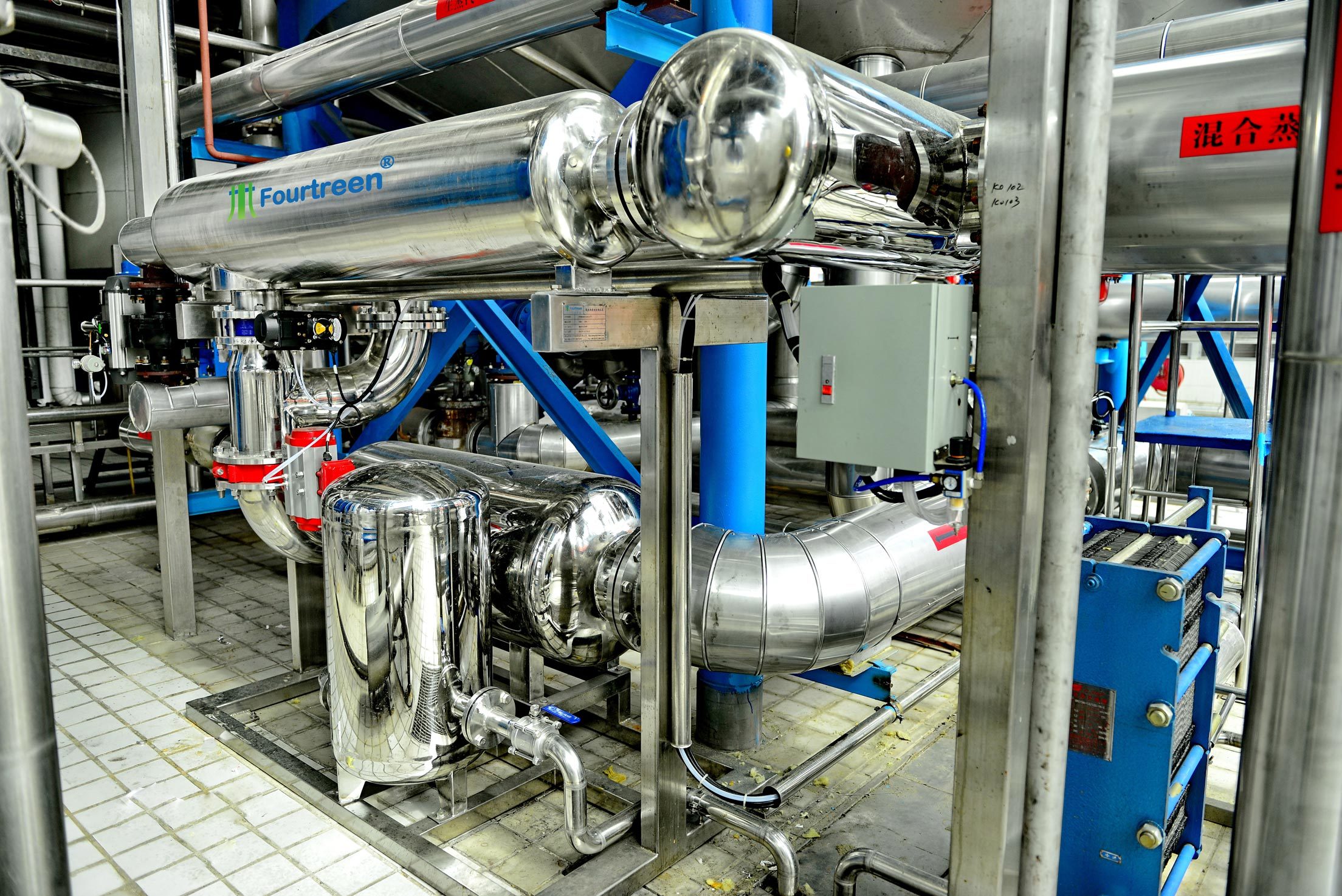

Tsingtao Beer HPR Energy Saving System

Project Introduction

Project background:The wort boiling process of beer production line consumes a large amount of raw steam and produces large of secondary steam in the continuous boiling stage. If the heat energy of these secondary steam is not effectively recovered, it will result in a large waste of thermal energy.

Energy saving measures:The HPR technology directly recovers the secondary steam generated by the wort boiling system. After being heated and pressurized,it is recycled and used in wort boiling, achieving significant energy saving and carbon reduction.

Energy saving effect:Achieve 23% energy saving for wort boiling process.

Project Scene

Copyright©2024 GuangDong Fourtreen Green Technology Co.,Ltd

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Add:501-2, Building 5, Shiyou Industrial City, Junan Town, Shunde District, Foshan City,Guangdong Province,China