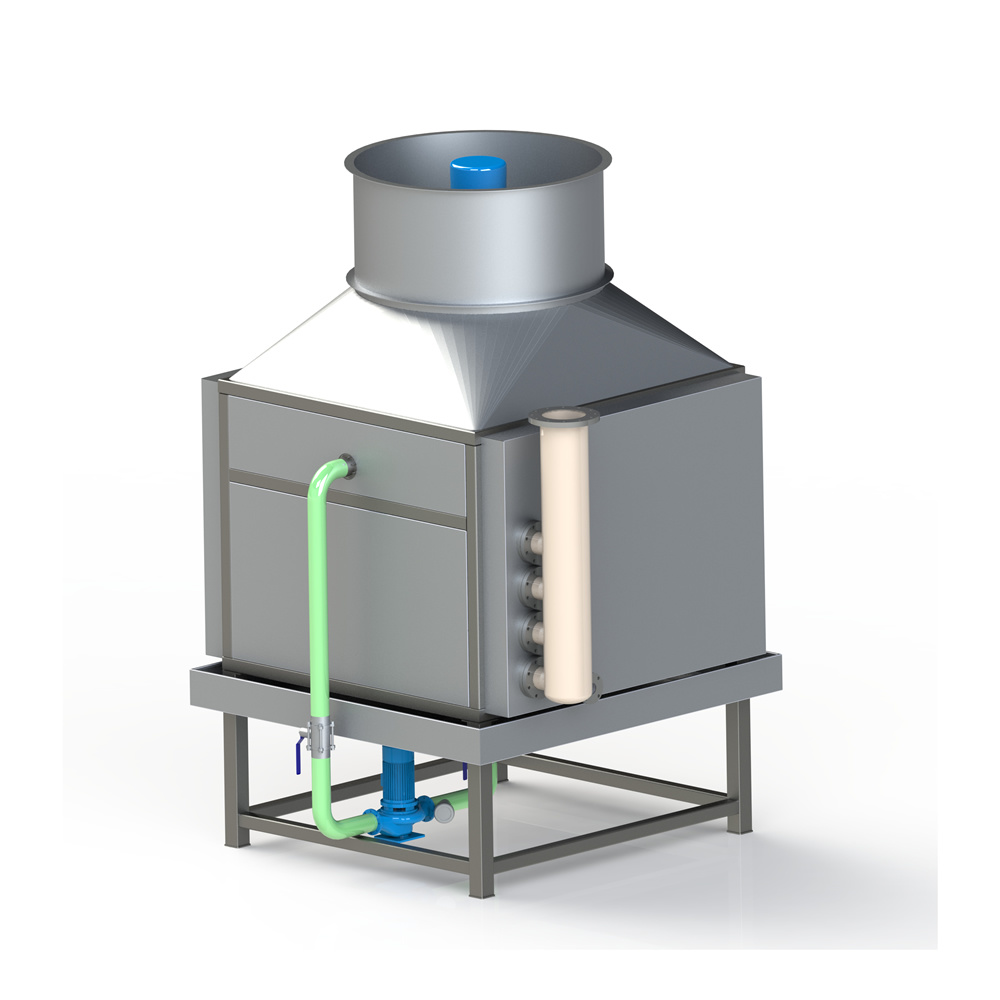

Spray Mass transfer Condenser (SMC)

Keywords: Fourtreen energy-saving equipment

Working principle

Product Advantages

● Efficient heat and mass transfer

After atomizing water into small droplets, it quickly vaporizes and takes away heat.

● Small water consumption

During the condensation process, water undergoes mass transfer and vaporization, consuming 70% less water than the traditional circulating water condensation method.

● Compact structure with limited space and investment

It can completely replace the evaporation and condensation system and does not require condensation heat exchangers, cooling towers, cooling ponds and circulating water pumps.

● Highly efficient energy saving

SMC saves more than 30% of electricity compared to traditional condensation systems and can provide a high-vacuum working environment for vacuum evaporation systems.

Application Case

Distiller's grains vacuum cooling system VCS

The VCS (vacuum cooling system) is equipped for the treatment of distiller's grains in the distiller's grains of liquor production, which realizes the green production effect of rapid cooling of high-heat distiller's grains and no emission of waste steam after opening the lid.

View Detailsimmediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Copyright©2024 GuangDong Fourtreen Green Technology Co.,Ltd

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Add:501-2, Building 5, Shiyou Industrial City, Junan Town, Shunde District, Foshan City,Guangdong Province,China