SOLUTION.

Through customized energy-saving and environmental protection technology solutions to achieve substantial energy-saving and emission reduction green production. Customized enterprise-specific production information cloud platform to achieve intelligent management of production information such as energy and quality.

Environmental protection industry

PRODUCTS.

Fourtreen's technology has been widely used in liquor production, pharmaceuticals, food/non-staple food processing, packaging, condiment production and many other industries.

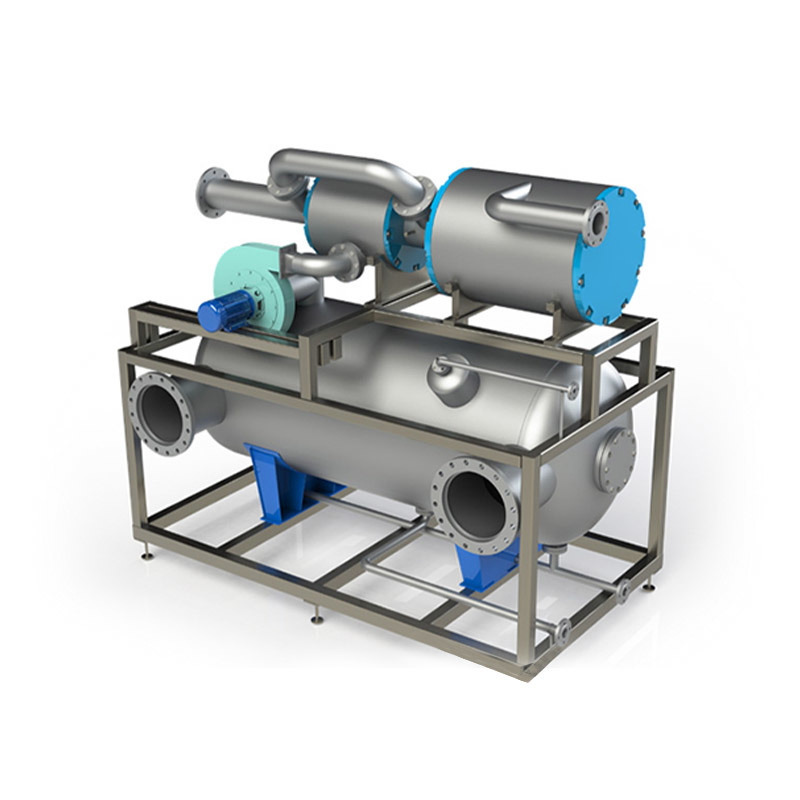

Waste Steam Recovery system with purifying & pressurizing (WSR)

Waste heat steam often contains impurities such as air and liquid droplets, making it difficult to be directly recycled. Through the WSR, impurities such as condensate and non-condensable gases in the waste heat steam can be removed to generate clean steam. Then it is compressed and heated up again and returned to the heat-consuming process for recycling.

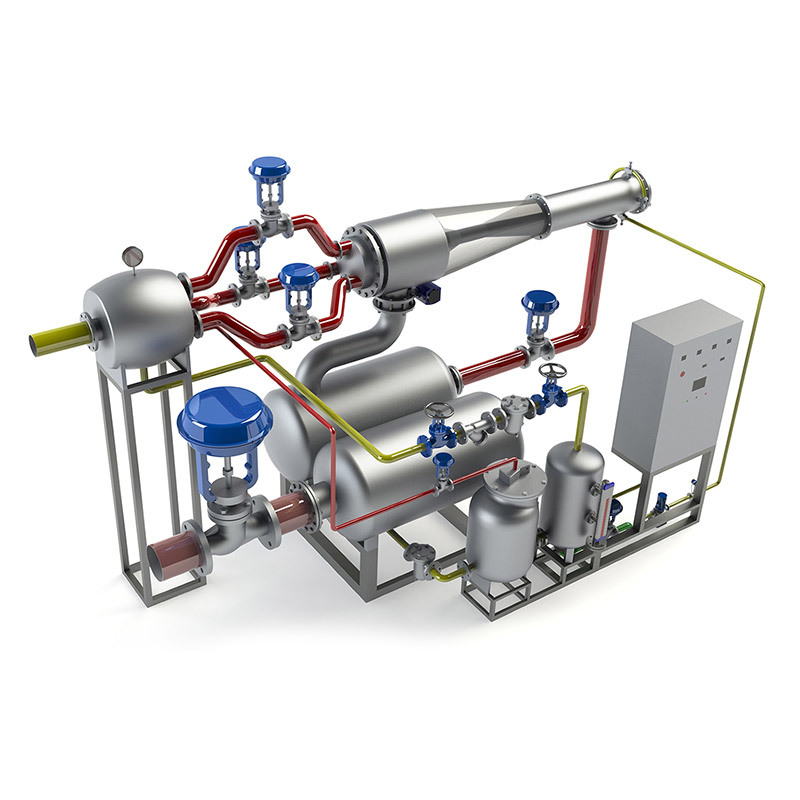

Intelligent Energy saving Distiller with Al (IED-AI)

● Through the unique vacuum low-temperature evaporation technology, the heat energy of wine vapor is extracted to generate fresh steam. Then, through the unique compression technical route, the low-pressure fresh steam is pressurized and heated up for recycling, achieving the energy-saving purposes of heat recycling and reducing the consumption of condensation cooling water. ● Equipped with an AI intelligent recognition system, by establishing models of vision and thermal working conditions, it realizes intelligent liquor picking by grading hop recognition instead of manual work, improving liquor picking efficiency and ensuring liquor picking quality.

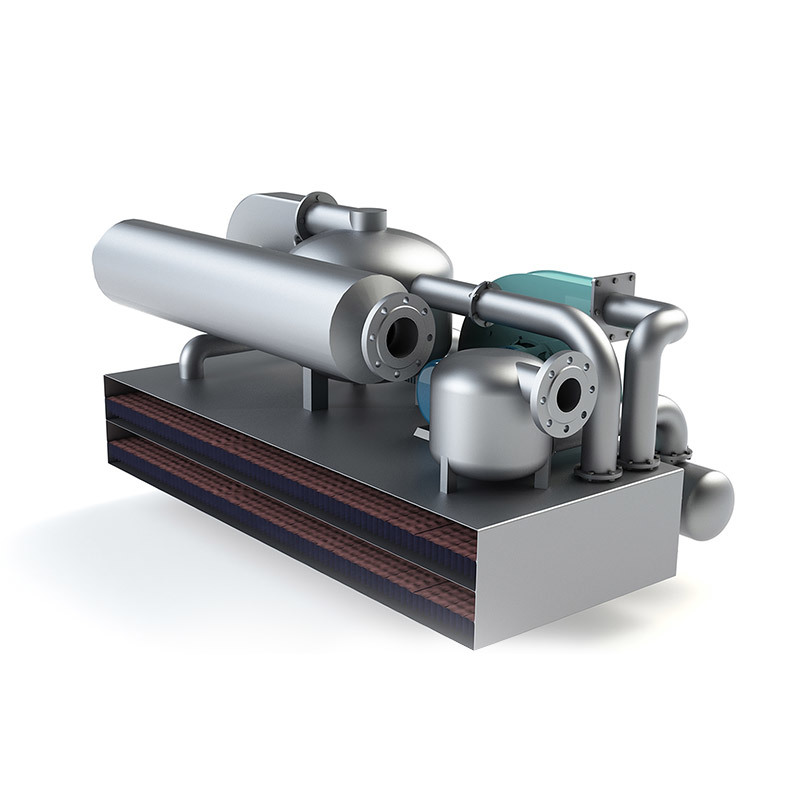

High efficiency Pressure stablizing system for waste heat Recovery (HPR)

By using live steam to do work and drive the equipment to operate, the secondary steam is compressed and heated up to achieve the energy-saving purpose of steam recycling.

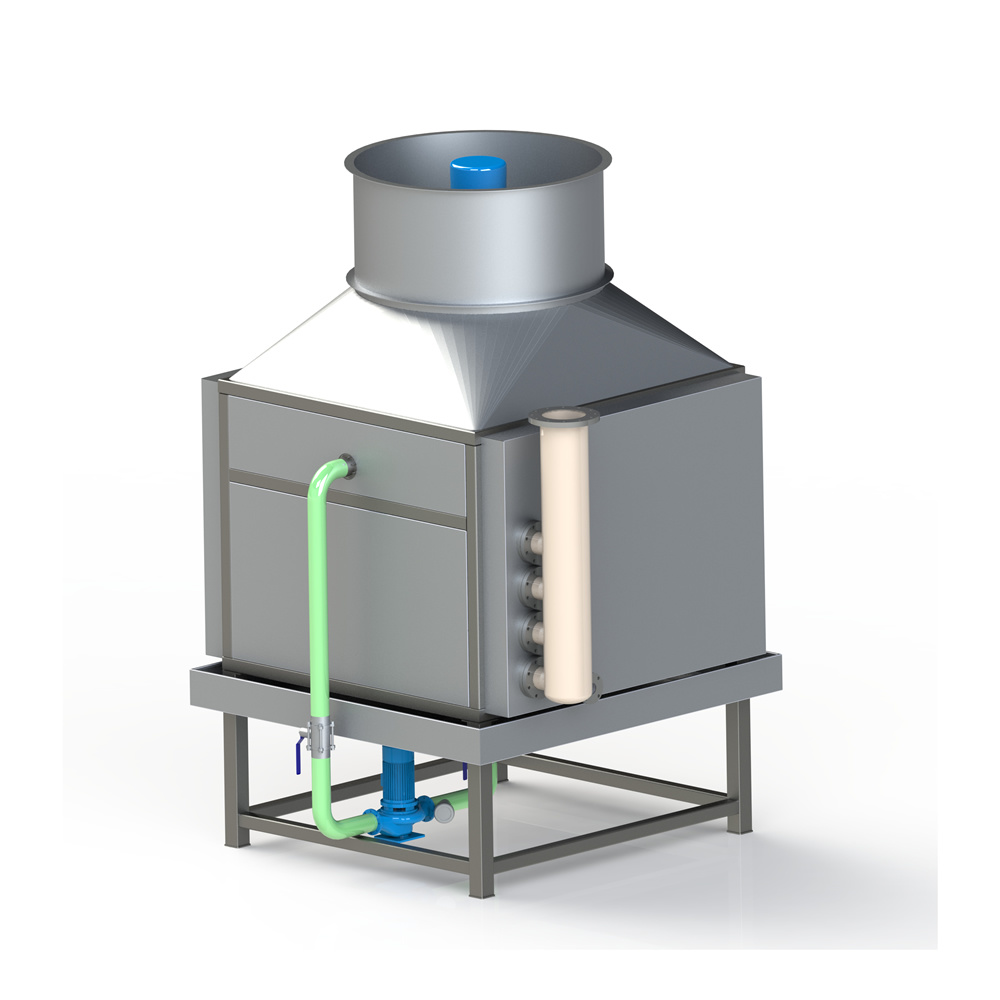

Spray Mass transfer Condenser (SMC)

The SMC integrates heat transfer and mass transfer effects. The heat transfer and mass transfer processes of water and air occur simultaneously and promote each other, achieving efficient heat transfer. The condensation and cooling speed is rapid. It saves more water and electricity than traditional condensation and cooling systems.

ABOUT US.

A green high-tech enterprise that has been committed to the research and development of innovative energy-saving and environmental protection technologies, the creation of industrial Internet platforms, and the implementation of automated and intelligent control solutions for many years.

Fourtreen Green Technology

COMPANY

GuangDong Fourtreen Green Technology Co.,Ltd.

Many years of intensive cultivation in the field of thermal energy saving, research and development/production/service supporting.

Own independent intellectual property rights of innovative low-grade waste heat recycling technology path.

Have numerous mature cases with excellent energy-saving benefits in the field of light industry.

SCIENCE GROW GREEN

NEWS.

Fourtreen news and industry trends.

Learn more about the latest company development, and grow together with Fourtreen.

Keep abreast of industry trends and grasp market information to respond to the change.

10

/

16

Recently, the Project Management Office of the Global Environment Facility (GEF) released the Public Notice List of the Second Batch of "Advanced Energy-Saving Technology and Product Application Demonstrations in the Boiler and Heat Exchanger Field" in China. After the collection and selection of advanced energy-saving technologies and products in this round, 12 domestic technologies and products finally stood out. Fourtreen successfully made the list with its "New Small Temperature Difference Steam Regeneration Technology". This is not only a recognition of Fourtreen's technical strength and innovative achievements at the national and even international levels, but also an important milestone in the company's efforts to promote industrial energy conservation and carbon reduction, and contribute to the achievement of the "dual carbon" goals!(This article only presents information about Fourtreen's inclusion in the application demonstration.)

09

/

26

Since 2020, China's energy and power sector has served as the primary battleground for achieving the dual carbon goals, with green development accelerating steadily. Market pricing, as the core indicator of resource value and the guiding principle for resource allocation, has effectively stimulated the vitality of green transformation. Currently, as the “dual carbon” efforts advance, new challenges have emerged. It is imperative to accelerate the refinement of electricity pricing mechanisms that align with the demands of the transition. This will better leverage the guiding role of prices, promote the transformation of economic development models, and inject sustained, powerful momentum into achieving the “dual carbon” goals. (Source: Yitanjia)(Image sourced from the Internet)

09

/

16

Southern Guangdong's Rising Stars: Fourtreen Among Them

Amidst the fertile ground of Guangdong, brimming with innovative vitality and boundless opportunities, the wave of brand building is surging forward. On September 11, the inaugural Guangdong Emerging Brands Launch Conference, hosted by the Guangdong Quality and Brand Development Alliance and co-organized by the Guangdong Price and Industrial Brand Development Association, Yangcheng Evening News, and Southern Rural News, was grandly held at the Yangcheng Creative Industry Park in Guangzhou. (Photo: Fourtreen representative second from left)